Bottle Making Machines for Efficient Packaging in 2025

Introduction to Bottle Making Machines

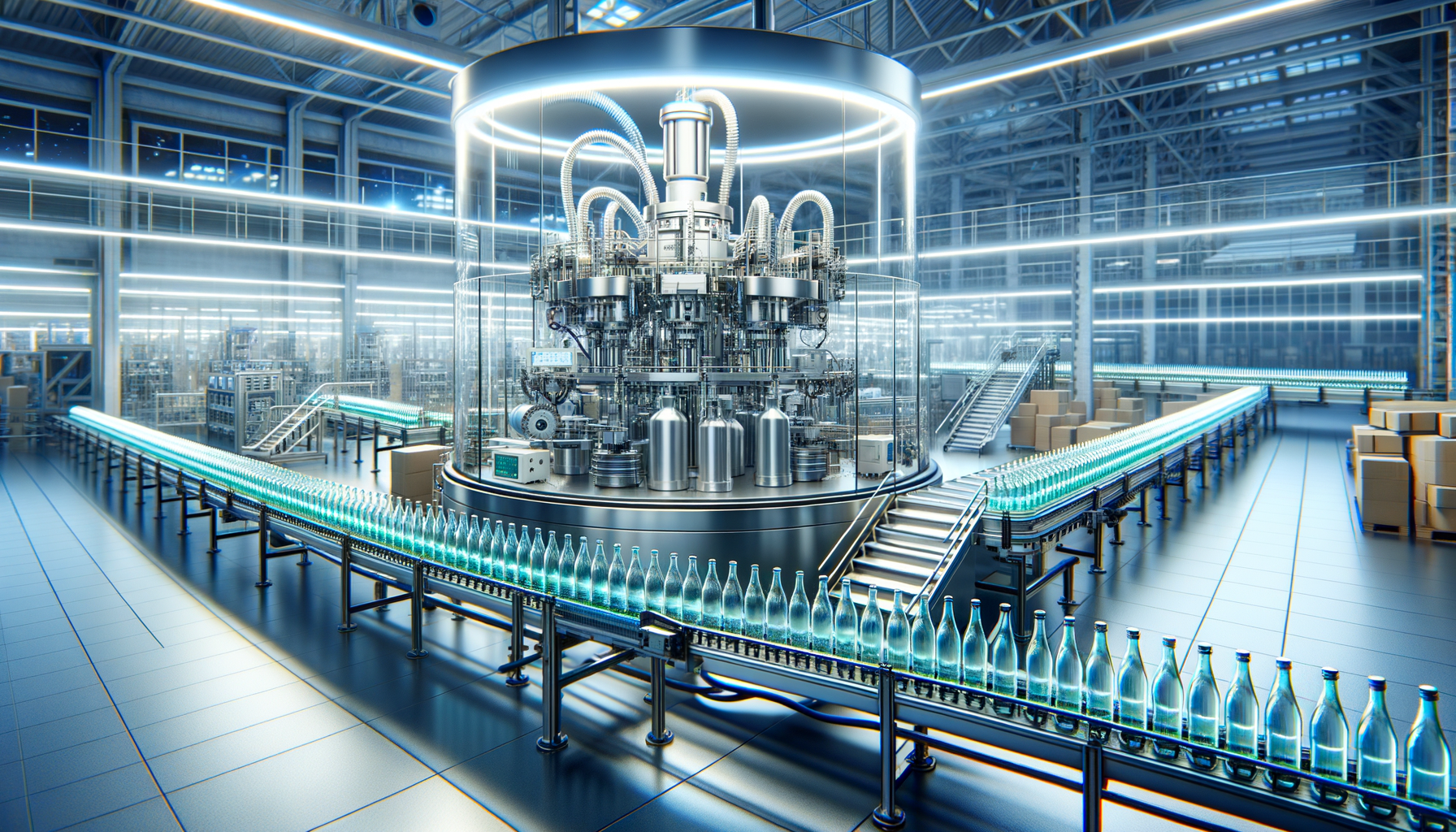

The packaging industry has witnessed significant advancements over the years, with bottle making machines playing a pivotal role in revolutionizing production processes. These machines have become essential for industries ranging from beverages to pharmaceuticals, facilitating efficient and high-quality packaging solutions. As we delve into the intricacies of bottle making machines, we uncover their importance in modern manufacturing and their contribution to sustainable business practices.

Bottle making machines are designed to automate the production of bottles, offering precision and consistency that manual methods cannot achieve. They cater to various materials, including plastic, glass, and metal, adapting to the diverse needs of different sectors. The rise of bottle making machines has not only enhanced productivity but also minimized waste, aligning with the growing emphasis on environmental sustainability.

The Mechanics of Bottle Making Machines

Understanding the mechanics behind bottle making machines is crucial for appreciating their role in industrial operations. These machines typically operate through a series of stages, starting with the melting of raw materials, followed by molding and cooling to produce the final bottle shape. The process is meticulously controlled to ensure uniformity and quality in every batch.

Modern bottle making machines are equipped with advanced technologies such as computer numerical control (CNC) and robotics, which enhance precision and efficiency. These technologies enable the machines to produce complex bottle designs with minimal human intervention. Additionally, the integration of sensors and automation software allows for real-time monitoring and adjustments, reducing downtime and maximizing output.

Advantages of Automatic Bottle Making Machines

Automatic bottle making machines represent a significant leap forward in manufacturing technology. These machines offer numerous advantages that make them indispensable in high-volume production environments. One of the primary benefits is their ability to operate continuously with minimal supervision, significantly reducing labor costs and increasing throughput.

Moreover, automatic machines are equipped with sophisticated quality control systems that detect defects and inconsistencies during the production process. This ensures that only bottles meeting stringent quality standards are dispatched, minimizing waste and enhancing customer satisfaction. The efficiency of automatic bottle making machines also translates to energy savings, as they are designed to optimize resource consumption without compromising performance.

Applications Across Industries

Bottle making machines are versatile tools that find applications across a wide range of industries. In the beverage sector, they are used to produce bottles for water, soft drinks, and alcoholic beverages, each requiring specific design and material considerations. The pharmaceutical industry relies on these machines to create sterile and secure bottles for medicines and health supplements.

Additionally, the cosmetics industry benefits from the precision and customization capabilities of bottle making machines, which allow for the creation of uniquely shaped containers that enhance brand identity. The adaptability of these machines to different materials and designs makes them a valuable asset for companies seeking to innovate and differentiate their products in competitive markets.

Future Trends and Innovations

As we look to the future, bottle making machines are poised to undergo further innovations that will shape the packaging industry. One emerging trend is the integration of smart technologies, such as the Internet of Things (IoT), which will enable machines to communicate with each other and optimize production processes autonomously. This will lead to even greater efficiencies and cost savings for manufacturers.

Another area of innovation is the development of eco-friendly materials and processes. With increasing environmental concerns, manufacturers are exploring sustainable alternatives to traditional plastics, such as biodegradable and recyclable materials. Bottle making machines are being adapted to accommodate these new materials, ensuring that the industry can meet environmental targets without sacrificing quality or performance.